As a cable assembly company, we are known for our way of co-engineering. Just like producing to the highest quality standards, this is in our nature. Now you may be thinking: But don't you work according to supplied drawings? Well, you may be surprised at how often we make the design or perfect the supplied design even further.

Making the impossible possible

With our almost 40 years of experience in cable assembly, we have already seen thousands of materials and parts from countless brands come by. This is particularly useful when (re)designing a cable assembly. Sometimes because we want to make the impossible possible, but sometimes also because we just don't think the original solution is good enough for the application.

Creative challenges

For example, a customer once wanted to use a small round connector to join four thin coaxial cables together. You may know that with coaxial cables it’s very important that the shielding of the cable should continue as long as possible in the connector housing to avoid interference with the signal. When using plain contacts instead of coax contacts, this is a challenge. Therefore, we found a ferrule for this purpose that proved suitable to put the four coax cables through there along with a wire for ground that was then also finished on one of the contacts. It may not sound very exciting, but you just have to think of it.

Coaxial cables and fiber optic parts

Speaking of ferrules: We have also used ferrules on coax cables that were actually intended as strain relief for fiber optic connectors. With a certain type of thin coax cable with a PTFE outer sheath, the regular ferrule did not stay in place well. PTFE (also known as Teflon) is rather smooth. The problem was solved with the special fiber optic ferrule.

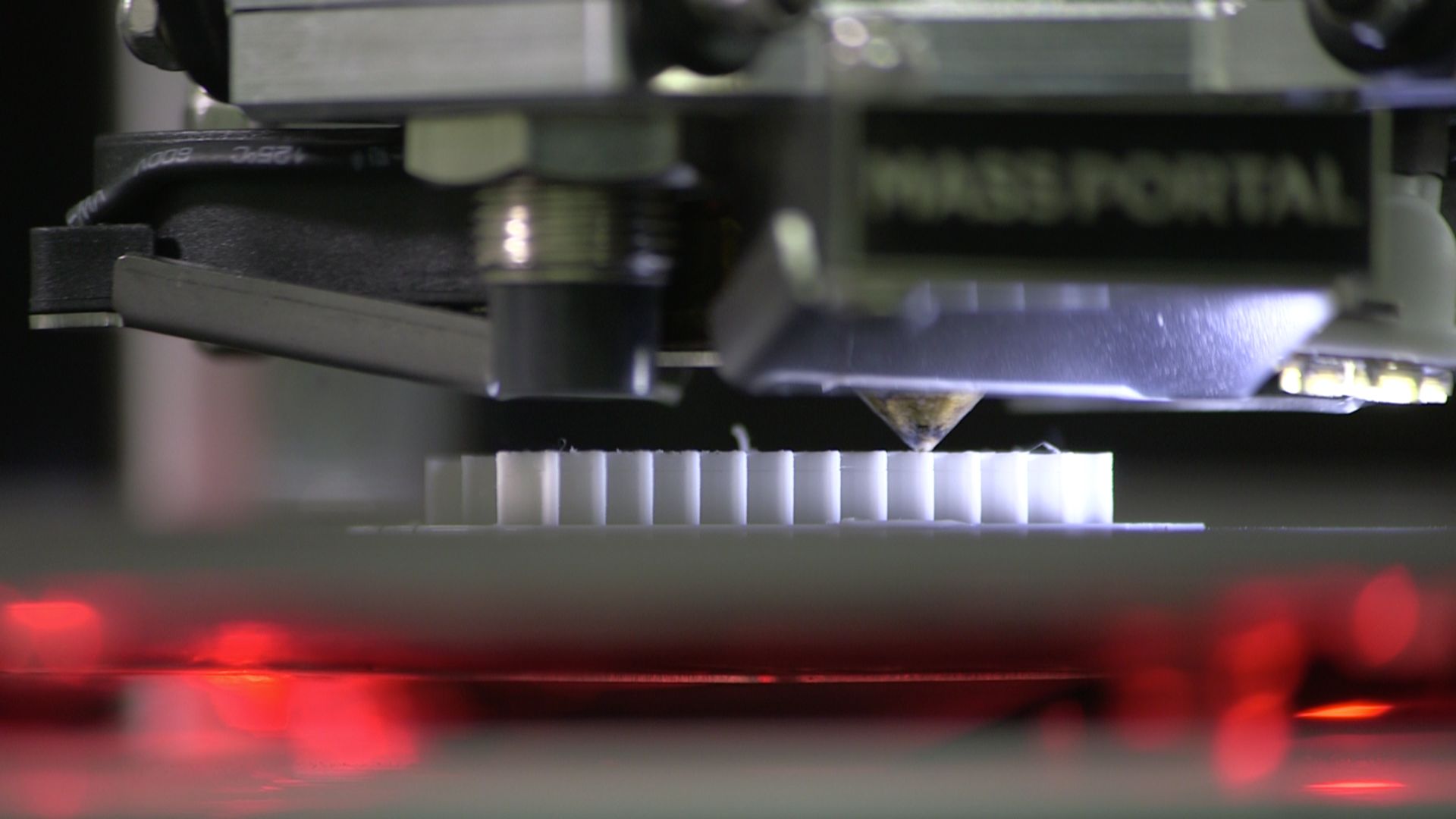

Stubborn for the best result

It also happens that we print certain components ourselves with our 3D printer. For example, we did this with a prescribed type of connector where we - as stubborn as we are - found that the wires were very vulnerable in the connector. A self-developed and printed bridge then protected the wires perfectly, after which our customer received cable assemblies that were even more reliable. That makes us happy.

Convinced

What does not make us happy is deviating from our quality standard. If we see that supplied wires do not match the contacts, a customer can jump so high and say we can just use it. No, we don't. Because we know that sooner or later the user will have problems with it. As creative as we are at MCAP, we know very well what can and cannot be done.

Do you have your own challenges in designing or optimising your cable assemblies? Then contact us without obligation and challenge us. We can't get enough of thinking creatively with you.